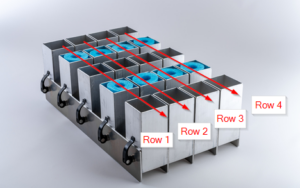

Racks like the Craig Co Rack shown in Figure 1 have tube holder angles that fan out within each row. This rack structure contrasts with Tiltable row racks in which the rows themselves tilt sideways to make fans.

Figure 1 – Fan row racks are usually rotated 90° in the rack layout so holders can fan out left/right from the audience perspective.

In Finale 3D there are two kinds of fan row racks — Pre-configured fan row racks, and Adjustable fan row racks. In the real world, the two kinds of fan row racks are usually the same physical hardware. The difference is in the design and planning phase. Do you want to pre-define the angles of your rack tube holders and design the show to fit in racks so configured, or do you want to let your show design dictate the angles of the tube holders in your racks?

Pre-configured fan row racks

The effects window contains various collections of effects like My Effects, Generic Effects, supplier catalogs, and possibly your company inventory in a single collection or spread out into multiple effects files (FDB files). You choose between different collections with the blue selector in the upper right of the effects window. The effects collections can contain racks, along with shells and other pyrotechnic devices. Every item in the effects list has a unique part number, which is the reference used when the effect is inserted into the show or when the rack is inserted into the rack layout.

When you make a rack configuration of one of your racks to add to the show as a pre-configured rack, you need to add the new rack definition representing the pre-configured rack as as item in one of your effects collections. That means you need to assign it a unique part number. Let’s say you use racks like the one shown in Figure 1. If you use 10 different configurations of this rack, then you would have 10 different items in your effects collection, representing the variations. Each one would need its own part number, but they are related since they are all configurations of the same physical hardware, so you might make a part number scheme for your variations that has a common stem, like PLS30-A, PLS30-B, PLS30-C, for three different configurations of PyroDigiT racks, or maybe PLS30-FAN, PLS-30-STRAIGHT, PLS-30-ANGLES, if part numbers like that are more recognizable.

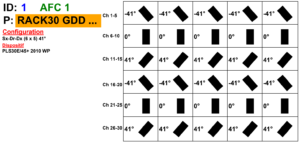

Figure 2 shows a possible configuration of a PyroDigiT fan row rack that requires pre-wired pins.

Figure 2 – Six row example in which all the tube holders in each row aim the same direction instead of fanning out.

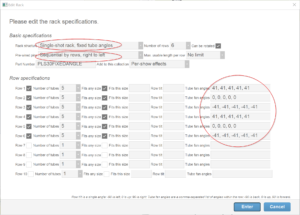

The corresponding rack configuration in Finale 3D is shown in Figure 3. You can invoke this dialog with the command “Racks > Create rack…”. The salient input fields are circled in red. The first indicated field defines the rack structure — “Single-shot rack, fixed tube angles”. The reason this is the correct selection, rather than any of the adjustable tube holder options, is that you are “pre-configuring” the rack. From the perspective of Finale 3D, none of the angles are adjustable.

Figure 3 – Rack definition corresponding to the pre-configure tube holder angle specifications of Figure 2.

The diagram of Figure 2 also specifies the pin numbers (“Ch” in the diagram) for all the tube holders, as is common for PyroDigiT racks with built in firing system rails. You will need to specify the pre-wired pin order in the second red circle of Figure 3 in your rack definition. The pre-wired pins option applies equally to pre-configured fan row racks and adjustable fan row racks.

Adjustable fan row racks

Adjustable fan row racks are usually the same hardware as pre-configured fan row racks, so Figure 1 could represent either. In Finale 3D, you define an adjustable fan row rack by setting the rack structure selector in the first red circle of Figure 3 to, “Single-shot rack, adjustable fan angle tubes in each row”. Having declared that the tube holder angles are adjustable, you obviously shouldn’t specify the angles within the rows, so the circled area on the right side of Figure 3 should be blank or should contain angle ranges instead of specific angles.

For most fan row racks, the tube holders at the ends of the rows can rotate significantly wider than the interior tube holders because the interior tube holders run into their neighbors when they lean far enough. You can represent the angle ranges in the rack definition following the instructions in Tube angle range constraints.

The Addressing algorithm that assigns firing system modules and pins to the effects also assign the racks and tube holders to the effects. The tube holder angles of adjustable fan row racks are undefined until effects are assigned to them, at which point the tube holder angles take on the angles of their effects. In this manner it can be said that the addressing algorithm chooses the tube holder angles of the adjustable fan row racks.